Containerized & Modular Push Floor for Biomass Storage and DischargeSERVODAY Hydraulic Moving Floor System

SERVODAY Hydraulic Moving Floor System also known as Push Floor, Moving Floor, Live Floor, SCHUBBODEN and more is a plug & play biomass storage and discharge solution for pellet plants, CBG plants, biogas plants and power plants. High capacity, low maintenance, fully automated modular system.

Reliable Biomass Extraction with Intelligent Hydraulic Precision

SERVODAY Hydraulic Moving Floor System

The SERVODAY Hydraulic Moving Floor System is an advanced bulk material storage and discharge solution designed for biomass, waste, and industrial fuel handling applications. Known globally by different names such as Push Floor, Moving Floor, Live Floor, Pull Floor, Live Bottom, Smart Floor, Sliding Floor, and SCHUBBODEN, this system ensures smooth, controlled, and automated material extraction. SERVODAY integrates heavy-duty hydraulic cylinders, abrasion resistant floor slats, and intelligent PLC control to deliver reliable performance in pellet plants, CBG plants, biogas plants, and power plants.

Optimized Biomass Feedstock Handling Systems for Biomass Material

The performance of any biomass-based plant depends on a steady supply of uniformly sized and properly conditioned biomass material. Inconsistent particle size, moisture variation, or irregular feeding can reduce process efficiency, affect pellet quality, disturb combustion, or lower biogas yield. SERVODAY GROUP provides integrated, heavy-duty solutions from size reduction and screening to conveying and intelligent storage designed to ensure continuous, homogeneous biomass flow. Our systems maximize operational uptime, improve conversion efficiency, and enhance overall plant performance and agility across pellet plants, CBG plants, biogas facilities, and biomass power projects.

Compact. Relocatable. Engineered for Rapid Deployment

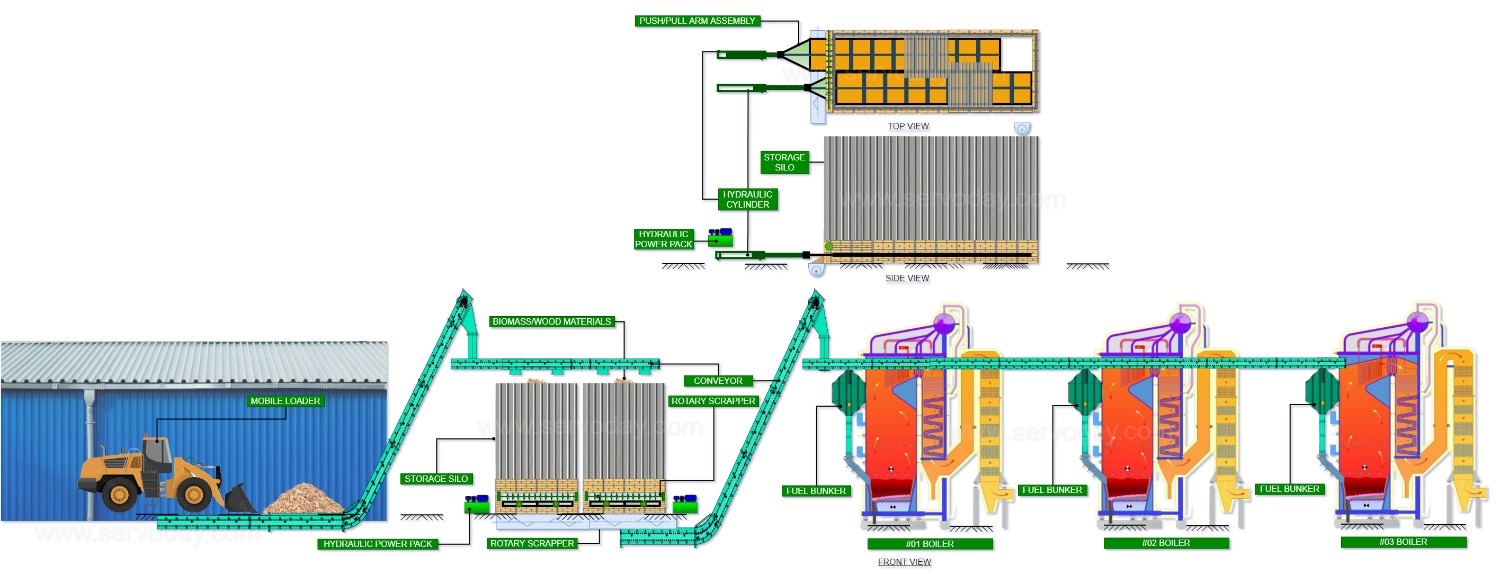

SERVODAY Containerized Hydraulic Moving Floor System

The SERVODAY Containerized Hydraulic Moving Floor System is a fully integrated plug & play solution installed inside standard containers. It reduces civil construction, minimizes installation time, and enables easy relocation. Ideal for modular pellet plants and decentralized CBG or biogas units, this version ensures rapid commissioning and minimal site dependency. It supports truck unloading, bulk storage, and controlled discharge into downstream conveyors or feeders.

Scalable Storage Strength with Faster On-Site Execution

SERVODAY Modular Hydraulic Moving Floor with Pre-Fabricated Side Walls

The SERVODAY Modular Hydraulic Moving Floor with Pre-fabricated Side Walls provides scalable storage capacities with fast erection. The pre-engineered steel walls ensure structural strength and reduce civil costs. Designed for high-volume biomass storage, it is suitable for large power plants and industrial fuel yards. The modular design allows capacity expansion as plant demand grows.

Turnkey Biomass Handling with Seamless Integration

Plug & Play Biomass Storage and Discharge System

SERVODAY offers a complete Plug & Play Biomass Storage and Discharge System engineered for seamless integration with screw conveyors, belt conveyors, and drag chain conveyors. The system includes hydraulic power pack, control panel, floor slats, structural frame, and automation package. Minimal foundation work and rapid installation make it ideal for fast-track renewable energy projects.

Globally Recognized Technology. Locally Delivered Performance

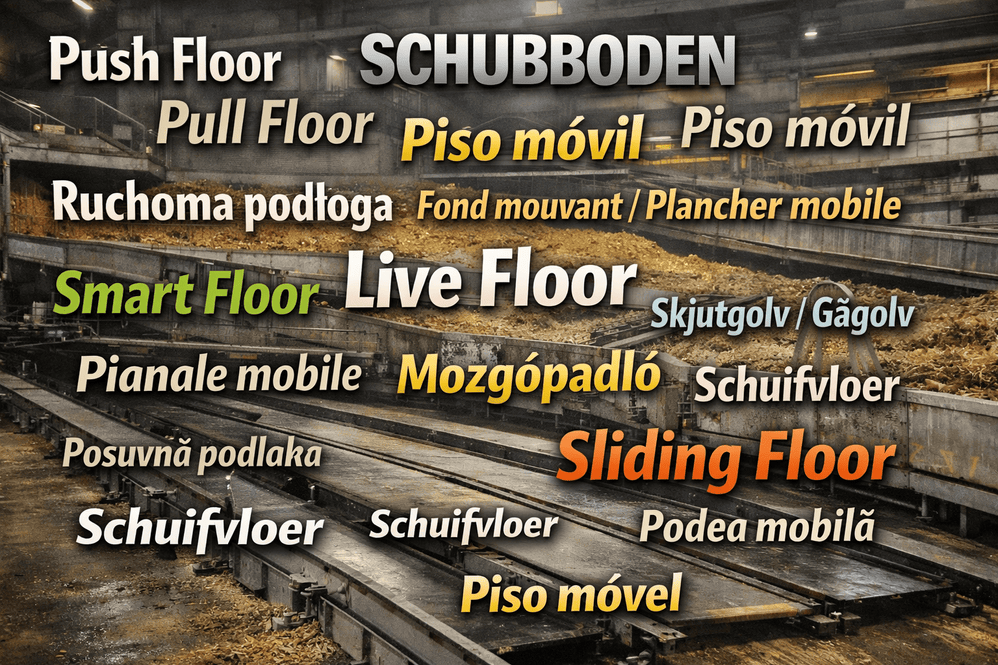

International Terminology and Global Acceptance

SERVODAY system is recognized globally under various names including SCHUBBODEN (Germany), Fond mouvant / Plancher mobile (France), Piso móvil (Spain), Pianale mobile (Italy), Schuifvloer (Netherlands), Ruchoma podłoga (Poland), Posuvná podlaha (Czech Republic), Piso móvel (Portugal), Skjutgolv / Gågolv (Sweden), Skubbebund (Denmark), Kävelevä lattia (Finland), Mozgópadló (Hungary), Podea mobilă (Romania), and Pis mòbil (Catalonia). This international acceptance proves the reliability and efficiency of SERVODAY technology in global markets.

pages.stores.usps.title

One Technology. Many Names. Trusted PerformanceGlobal Hydraulic Moving Floor Systems | SERVODAY

SERVODAY is the leading manufacturer of hydraulic moving floor systems. Known globally as SCHUBBODEN, Fond mouvant, Piso móvil, Pianale mobile, Schuifvloer, Push Floor, Moving Floor, Live Floor, and more.

Uniform Feeding for Superior Pellet Quality

Applications in Pellet Plants

In pellet plants, SERVODAY Hydraulic Moving Floor ensures uniform feeding of raw materials into hammer mills and dryers. It prevents bridging, ensures steady output, and supports continuous plant operation. It handles sawdust, wood chips, rice husk, and agro residues efficiently, improving pellet quality consistency and plant productivity.

Stable Biomass Flow for Higher Gas Yield

Applications in CBG Plants

For CBG plants, SERVODAY systems manage agricultural residues and organic biomass with controlled feeding into shredders or digesters. Consistent material flow improves gas yield and stabilizes digestion processes. The hydraulic walking floor handles high-moisture biomass without clogging.

Handling Low-Density, High-Moisture Biomass with StabilityIntegrated Pyrolysis and Anaerobic Digestion Plant

At an integrated pyrolysis and AD facility processing wet agro-residues and organic waste, material bridging and uneven discharge disrupted operations. The SERVODAY Hydraulic Moving Floor System ensured uniform extraction despite low bulk density and high moisture. Its sequential hydraulic slats prevented clogging, stabilized feed rates, and maintained continuous reactor and digester performance.

Automated Feeding for Optimized Methane Output

Applications in Biogas Plants

In biogas plants, the SERVODAY Moving Floor system ensures automated feeding of feedstock into mixing pits and digesters. It reduces manual handling, enhances hygiene, and maintains steady organic loading rates, improving methane generation efficiency.

Continuous Fuel Supply for Uninterrupted Power Generation

Applications in Biomass Power Plants

Biomass power plants benefit from SERVODAY Live Floor systems through continuous and controlled fuel feeding into AFBC and CFBC boilers. It ensures uninterrupted combustion, reduces manpower, and enhances fuel stock management.

Reliable Storage and Controlled Discharge of Fibrous Energy Crops Napier Grass Feeding System for CBG Plant

CBG plant using freshly harvested Napier grass faced severe flow blockages due to its fibrous, lightweight structure and high moisture. The SERVODAY Hydraulic Moving Floor System enabled consistent, metered feeding into shredders and digesters. The walking floor eliminated rat-holing, improved gas yield stability, and ensured uninterrupted plant operation .

Versatile Handling Across Diverse Biomass Materials

Materials Handled by SERVODAY System

The SERVODAY Hydraulic Moving Floor can store and discharge rice husk, sawdust, wood chips, wood shavings, planer shavings, bagasse, sugarcane trash, corn stalks, maize stover, wheat straw, paddy straw, cotton stalks, groundnut shells, coconut shells (crushed), palm fiber, palm leaves, mustard husk, sunflower husk, coffee husk, RDF, MSW fluff, napier grass, bamboo chips, forestry waste, bark, and shredded municipal waste.

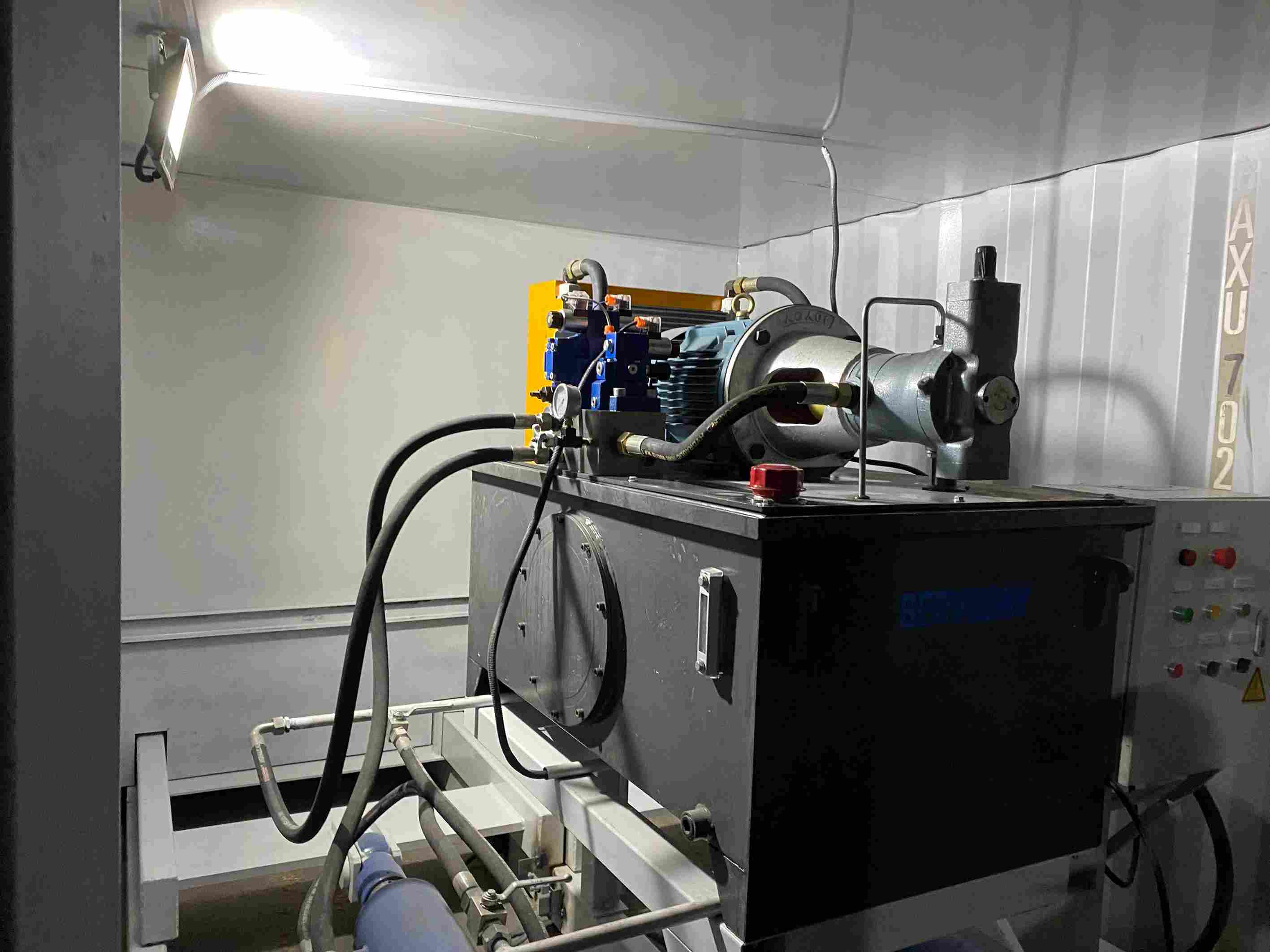

Heavy-Duty Hydraulics with Intelligent Motion Control

Technical Features

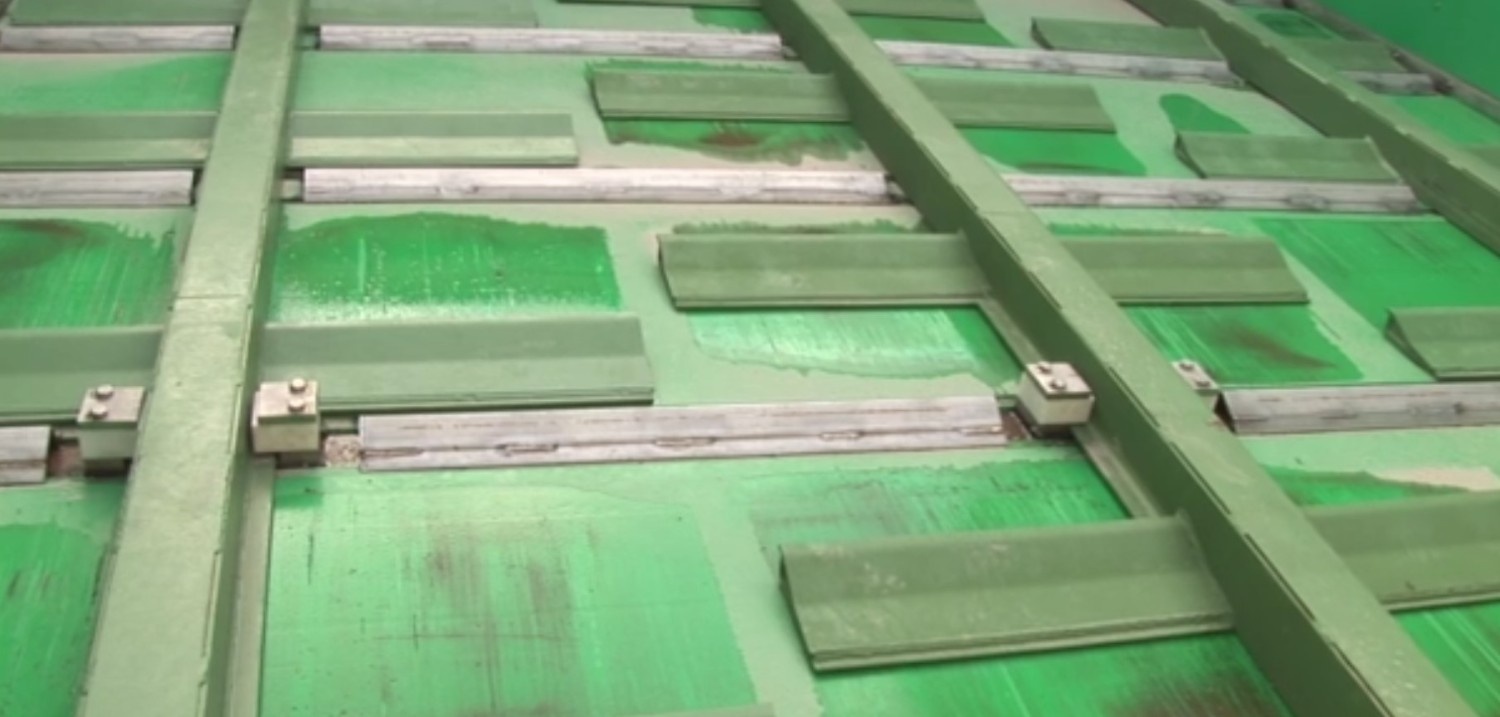

SERVODAY systems use heavy-duty hydraulic cylinders with sequential reciprocating motion to move floor slats. The slats advance material forward during the power stroke and retract independently to prevent backflow. The system operates through PLC-controlled automation with variable discharge speed options. High-torque hydraulic power packs ensure consistent performance under heavy load.

Controlled Extraction. Maximum Equipment Protection

Operational Advantages

SERVODAY Moving Floor systems eliminate bridging and rat-holing common in traditional hoppers. They provide uniform discharge across the bunker width. The controlled extraction prevents sudden load shocks on downstream equipment, extending equipment life and reducing maintenance.

Rugged Construction Built for Demanding Biomass Loads

Structural and Design Benefits

SERVODAY floor slats are fabricated from high-strength abrasion-resistant steel. The structural frame is engineered for heavy bulk densities and high moisture content materials. The modular wall design reduces civil work and enhances installation flexibility.

Efficient Reclaim of Lightweight Biomass for Continuous Combustion Low-Density Fuel Handling for Industrial Energy Plants

In a power plant and waste-to-energy facility handling RDF fluff and light biomass, conventional hoppers failed due to poor material flow. The SERVODAY Hydraulic Moving Floor System provided wide-area extraction and controlled discharge. It maintained steady boiler feeding, reduced downtime, and optimized combustion efficiency across varying fuel densities.

Smart Monitoring for Precision Discharge Management

Automation and Control

SERVODAY Smart Floor integrates PLC panels, sensors, and optional SCADA connectivity. Operators can control discharge rate, monitor hydraulic pressure, and adjust stroke frequency. Remote monitoring enables predictive maintenance and efficient plant management.

Higher Efficiency with Lower Civil and Maintenance Costs

Benefits Over Conventional Systems

Compared to traditional silos or grab feeding systems, SERVODAY Push Floor offers better control, lower maintenance, reduced manpower, and improved safety. It eliminates the need for complex reclaim tunnels and reduces capital expenditure on civil infrastructure.

Tailored Capacities for Every Plant Requirement

Customization and Capacity Range

SERVODAY Hydraulic Moving Floor Systems are available in various widths and lengths depending on storage capacity requirements. Capacities can range from small modular 20–50 cubic meter units to large industrial bunkers exceeding 1000 cubic meters. Custom designs are provided based on bulk density, moisture content, and plant throughput requirements.

Proven Engineering. Trusted Biomass Handling Solutions

Why Choose SERVODAY

SERVODAY combines engineering expertise, robust fabrication, and advanced automation to deliver reliable biomass storage solutions. With global terminology acceptance such as SCHUBBODEN, Plancher mobile, Piso móvil, and others, SERVODAY stands as a trusted partner for renewable energy, waste-to-energy, and industrial fuel handling projects.

Inquire About SERVODAY Hydraulic Moving Floor System

Are you ready to optimize your material handling and storage operations with reliable, efficient technology? Contact us today to request a quote for the SERVODAY Hydraulic Moving Floor System. Discover the perfect solution tailored to your specific feedstock requirements, offering a customized quote that aligns with your budget and operational needs.

Precision Feeding for Optimal Gasification

Custom-Engineered for Syngas Boilers

SERVODAY provides customized boiler feeding solutions specifically engineered for bio-methanol plants. Our systems are tailored to handle the specific fuel characteristics of feedstocks like wood chips, eucalyptus, and industrial biomass residues, ensuring precise and reliable fuel delivery to CFB, BFB, and gasifier boilers for superior syngas quality and consistent methanol output.

Expert Support for Peak Hydraulic Moving Floor Performance

Reliable System Operation Through Comprehensive Training and Technical Assistance

SERVODAY ensures your team achieves mastery with extensive training programs focused on Hydraulic Moving Floor System operation. From material handling best practices and system maintenance to troubleshooting specific to hydraulic drive mechanisms, our training maximizes operational efficiency, safety, and the longevity of your complete moving floor system.