SERVODAY Wood Biomass Pellet Plants: The Engineered Feedstock for Superior Bio-Methanol Yield & Profitability

Complete Bio-Methanol Plant Solutions: Pellet Plant, Chippers, Conveyors, Storage & Dryers

SERVODAY engineers precision plants & equipment for bio-methanol plants: Pellet Plant, high-volume wood chippers, efficient belt conveyors, controlled moving floor storage, and rotary drum dryers. Ensure feedstock uniformity, continuous flow, and optimal syngas quality for maximum methanol production efficiency.

SERVODAY Turnkey Pellet Plants: Optimized Feedstock for Bio-Methanol Production

Engineering Uniform, High-Yield Pellets for Superior Gasification and Syngas Quality

SERVODAY delivers complete turnkey wood and biomass pellet production plants specifically engineered to create the ideal feedstock for bio-methanol synthesis. As your single-source provider, we manage every phase from concept and design to manufacturing, installation, commissioning, and training. Our plants produce highly uniform, dense pellets with consistent moisture content and particle size, which are critical for achieving stable, efficient gasification. This optimized feedstock prevents channeling and clinkering in the gasifier, maximizes syngas (H₂ + CO) yield, and improves the overall efficiency of your methanol synthesis loop. With capacities from 1 to 25 TPH, our solutions are designed to provide a reliable, high-quality fuel supply that enhances calorific value, simplifies handling and storage, and ensures seamless integration with downstream methanol production processes. Trust SERVODAY to build the foundation for maximum methanol output and operational reliability.

Optimized Biomass Feedstock Handling Systems for Methanol Production

The efficiency of a modern bio-methanol plant hinges on a reliable, high-volume supply of uniformly sized wood chips. Inconsistent feedstock can cripple gasification efficiency, leading to downtime and lost revenue. SERVODAY GROUP provides integrated, robust machinery—from primary chipping and conveying to intelligent storage—engineered specifically to meet the rigorous demands of methanol production. Our systems ensure a continuous, homogeneous flow of premium biomass feedstock maximizing your plant's operational uptime and conversion yield.

for conversion,

performance, and agility.

SERVODAY Precision-Cut Chips for Maximum Methanol YieldSERVODAY Rotary Drum Wood Chipper for Bio-Methanol Production

SERVODAY Rotary Drum Wood Chippers deliver precision-cut, uniform feedstock for stable gasification and maximum efficiency in bio-methanol production

SERVODAY: The Precision Chipper for Bio-Methanol Feedstock

Engineered for Precision and Volume in Bio-Methanol Production

The SERVODAY Rotary Drum Wood Chipper is the cornerstone of your biomass preprocessing system. It is specifically engineered to convert raw hardwood and softwood logs, slabs, and residues into high-quality, uniform wood chips that are ideal for gasification in methanol plants. Superior chip uniformity ensures consistent flow, optimal syngas composition, and maximum efficiency in the downstream gasification and synthesis processes. Built for 24/7 industrial operation, it delivers unparalleled throughput and reliability.

Chip Uniformity for Stable Gasification. Built SERVODAY Tough

Application & Importance for your Methanol Plants

This chipper is designed for the primary size reduction of biomass feedstock. Its primary application is to create a consistent, clean chip that allows for efficient drying, conveying, and, most importantly, controlled gasification. Uniform chip size is non-negotiable for methanol plants; it ensures even heat transfer and reaction rates in the gasifier, preventing channeling, clinkering, and syngas quality fluctuations.

SERVODAY Chippers: Perfectly Scaled for Your Plant's Capacity

Suggested Capacity for your Methanol Plants

• For a 100 TPD Methanol Plant: Requiring ~466 MT of wood chips per day (at 50% moisture), a continuous feed of ~19.4 MTPH is needed. The Model SWC-40/105 (18-28 TPH capacity) is perfectly suited, providing necessary headroom for maintenance and peak operation. • For a 250 TPD Methanol Plant: Requiring ~1,165 MT/day (~48.5 MTPH), multiple units like the Model SWC-33/105 or a larger custom-configured chipper would be recommended. • For a 500+ TPD Methanol Plant: A fleet of high-capacity chippers or a custom-designed stationary chipper system is required to meet the significant feedstock demand.

SERVODAY Advantages: Superior Chip Quality & Maximum Uptime

Advantages & Benefits

• Superior Chip Uniformity: Precision knives and anvil adjustment guarantee consistent chip size, critical for stable gasification. • High Availability & Uptime: Quick-change knife systems, centralized lubrication, and robust construction minimize downtime for maintenance. • Wide Material Flexibility: Efficiently processes a vast range of feedstocks, including tough hardwoods (oak, maple) and softwoods (pine, spruce), as well as bamboo and forestry residues. • Operational Efficiency: Powered infeed rollers and an anti-clogging design ensure smooth, continuous operation with minimal operator intervention. • Built for Scale: With models offering up to 28 TPH capacity, SERVODAY chippers are designed to meet the massive daily feedstock requirements of your industrial methanol facilities.

SERVODAY Side Wall Rubber Belt ConveyorsThe Reliable Conveying System

Heavy-Duty Side Wall Rubber Belt Conveyors for Biomass Feedstock Transfer

SERVODAY Conveyors: The Efficient Link in Your Processing Chain

Seamlessly Connecting Your Methanol Plant's Preprocessing Chain

SERVODAY's Side Wall Rubber Belt Conveyors are engineered for the tough job of transporting abrasive wood chips from the chipper output to storage piles, dryers, and ultimately the gasifier feed system. They provide a faster, cleaner, and more economical transport solution compared to front-end loaders and pneumatic systems. Designed for steep inclines and long distances, these conveyors ensure a continuous, spill-free flow of material, which is vital for maintaining the steady feedstock supply a methanol plant requires.

The Backbone of Your Plant: Reliable SERVODAY Conveyor Systems

Application & Importance for your Methanol Plants

These conveyors form the material handling backbone, connecting all stages of feedstock preparation: 1. Transporting fresh chips from the chipper to storage or pre-drying areas. 2. Moving chips from storage to the drying system. 3. Feeding dried chips into the gasifier feed lock hoppers. Their reliability is crucial; any failure in conveying can halt the entire methanol production process.

SERVODAY: Custom Conveyor Solutions for Any Plant Size

Suggested Capacity for your Methanol Plants

Conveyor selection must match the chipper's output and the plant's consumption rate with a safety margin. • For a 100 TPD Plant: A SERVO-BC1000 (4-12 TPH) model is a starting point, but systems are often custom-designed for specific layouts and capacities, frequently requiring wider belts and higher speeds to handle the ~20 MTPH flow. • Larger plants will require custom-engineered conveyor systems with appropriate belt widths, roller grades, and drive power to handle hundreds of tonnes per hour.

Conveyor Benefits: Low Cost, Gentle Handling, Easy Integration

Advantages & Benefits

• High Efficiency & Low Operating Cost: Significantly more energy-efficient than using mobile equipment for material transfer over fixed paths. • Minimal Degradation: Gentle handling preserves chip integrity and reduces the creation of fines and dust, which can cause issues in downstream processes. • Enclosed Options Available: Can be covered to protect feedstock from moisture and prevent dust emissions, ensuring quality control and environmental compliance. • Low Maintenance: Robust design with simple idlers and belt systems ensures long service life and minimal upkeep. • System Integration: Perfectly integrated with SERVODAY chippers and moving floor storage systems for a seamless turnkey solution.

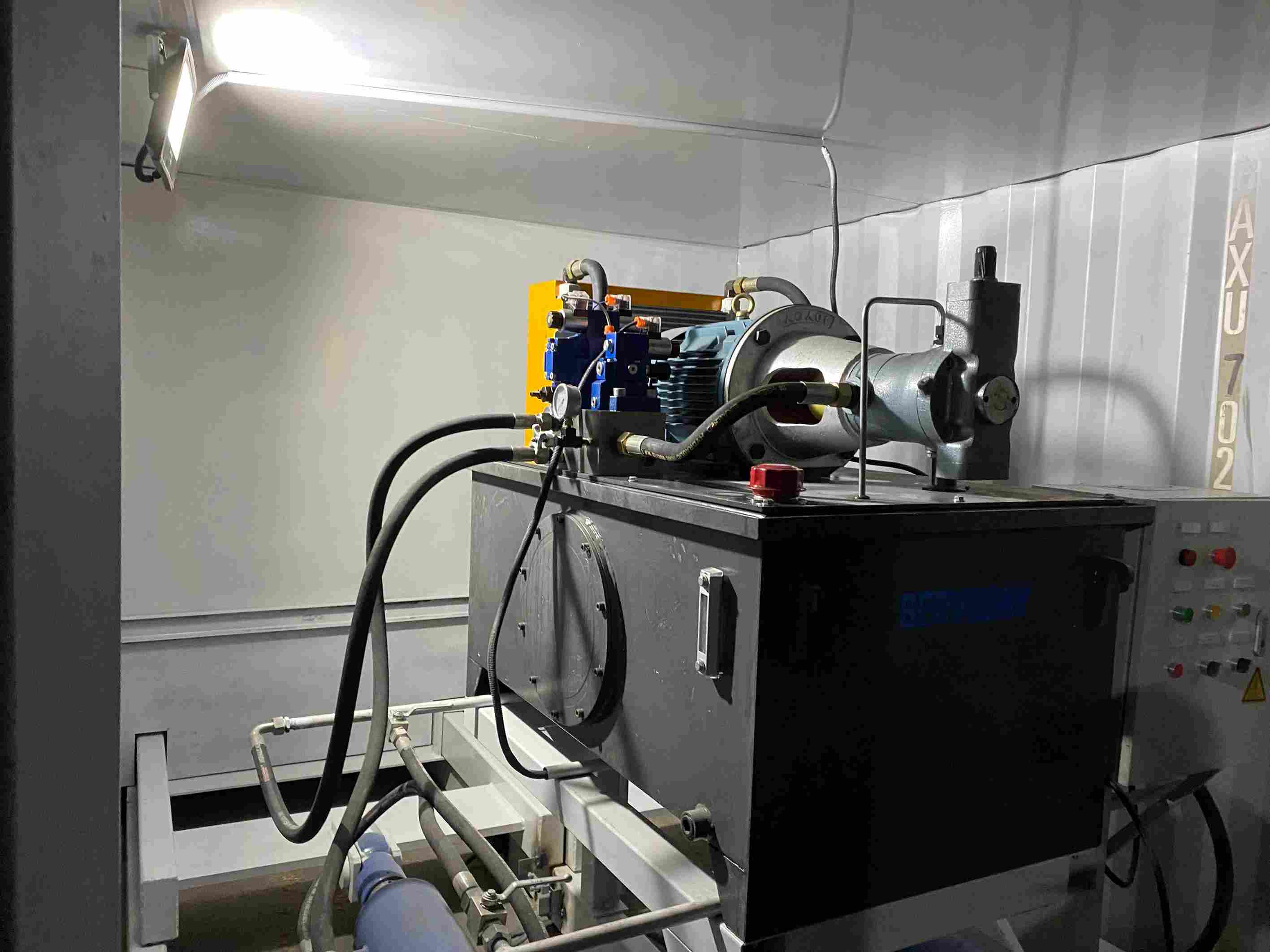

Intelligent Storage & Reclaim SERVODAY Containerized Hydraulic Moving Floor System

Containerized Hydraulic Moving Floor for Live Storage & First-In-First-Out Reclaim

SERVODAY Moving Floors: Revolutionized Controlled Biomass Storage

Ensuring Feedstock Consistency and Plant Availability for Methanol Production

The SERVODAY Containerized Hydraulic Moving Floor system revolutionizes biomass storage for your methanol plants. This system provides compact, efficient, and fully controlled live storage for wood chips. Its hydraulic moving floor slats create a "walking floor" action that gently and reliably discharges stored material at a precise, controlled rate. This technology is essential for bridging the gap between batch feedstock delivery and the continuous, 24/7 demand of the methanol synthesis process.

Solve Critical Storage Challenges with SERVODAY's FIFO Technology

Application & Importance for your Methanol Plants

This system solves several critical challenges: • Buffer Storage: It acts as a surge bin between incoming truck deliveries and the constant consumption of the plant. • First-In-First-Out (FIFO) Reclaim: Ensures the oldest feedstock is used first, preventing spoilage and degradation of stored chips, which is critical for maintaining consistent moisture content and gasification quality. • Dosage Control: Provides a metered, consistent discharge rate to the downstream conveying system, which is essential for stable gasifier operation.

SERVODAY Storage: Scalable Buffer for Uninterrupted Production

Suggested Capacity for your Methanol Plants

Storage capacity is based on plant consumption and delivery logistics. • A 100 TPD Plant consumes ~466 MT/day. A SERVO-40FT-4C-3S-840 system provides 840 M³ of storage. Assuming a wood chip bulk density of ~0.25 MT/M³ (for loose chips), this holds approximately 210 Metric Tonnes, providing over 10 hours of live storage buffer. • Plants often require multiple such modules or larger custom silos to store several days' worth of feedstock to safeguard against supply chain disruptions.

Moving Floor Benefits: Guaranteed Flow, Full Emptying, Low Power

Advantages & Benefits

• Guaranteed Flow: Eliminates bridging, rat-holing, and erratic flow common in static hoppers, ensuring a continuous feed to the process. • Total Space Utilization: The moving floor action ensures complete emptying of the storage container, leaving no dead zones. • Low Power Consumption: Hydraulic system is highly efficient, operating only when discharge is required. • Minimal Material Degradation: Gentle sliding action does not crush or pulverize the chips, preserving quality. • Modular & Scalable: Containerized design allows for easy expansion of storage capacity as plant production scales up.

Optimizing Feedstock for Gasification Product SERVODAY Rotary Drum Dryer

Industrial Rotary Drum Dryer for Wood & Biomass in Methanol Production

SERVODAY Dryers: Critical Moisture Control for Superior Syngas

Critical Moisture Control for Superior Syngas Yield and Plant Efficiency

The SERVODAY Wood & Biomass Rotary Drum Dryer is an indispensable component in the bio-methanol production chain, engineered to precisely reduce the moisture content of wood chips. High moisture in feedstock drastically reduces gasifier temperature, syngas quality, and overall plant efficiency. By efficiently removing moisture through a controlled, high-temperature process, our dryer transforms raw, wet wood chips into an optimized, energy-dense fuel, ensuring stable combustion and maximized syngas (H₂ + CO) production for the methanol synthesis loop.

Optimize Gasifier Efficiency with SERVODAY Drying Technology

Application & Importance for your Methanol Plants

This dryer's primary application is preconditioning the biomass feedstock between storage and the gasifier. Moisture is the enemy of efficient thermochemical conversion. • Energy Efficiency: Removing water reduces the energy required to heat and vaporize the feedstock in the gasifier, allowing more energy to be directed toward the breakdown of wood into syngas. • Syngas Quality: Dry feedstock leads to higher temperatures in the gasifier, which promotes endothermic reactions that produce a higher quality syngas with a better H₂/CO ratio, ideal for methanol synthesis. • Process Stability: Consistent moisture content in the feed is critical for controlling the gasification process, preventing temperature fluctuations, and ensuring smooth, continuous operation.

SERVODAY Dryers: Precisely Sized for Your Plant's Moisture Removal Demands

Suggested Capacity for your Methanol Plants

The dryer must be sized to handle the plant's total wet feedstock requirement. • For a 100 TPD Methanol Plant: Processing ~466 MT of wet chips (50% moisture) per day requires removing ~233 MT of water. The goal is to reduce moisture to 10-15%. A dryer must handle an input of ~19.4 MTPH of wet chips. The SERVO-SRD2.2-22 model (8 TPH capacity) would be a baseline, but larger, custom dryers are typically needed for this scale. • Larger plants require massive, custom-engineered drying systems, often with multiple drums or very large units, to process hundreds of tonnes per hour.

Maximize Syngas Output and Cut Costs with SERVODAY Drying Technology

Advantages & Benefits

• Maximized Gasifier Output: Directly increases the calorific value of the feedstock, leading to more syngas production per tonne of wood. • Enhanced Process Control: Delivers feedstock with consistent, predictable moisture levels, allowing for precise control of the gasification process. • Robust and Continuous Operation: The rotary drum design is proven for 24/7 industrial operation, handling abrasive wood chips with minimal downtime. • Energy Integration: Can be designed to utilize waste heat from the methanol synthesis or gasification process (e.g., engine exhaust, syngas cooler output), dramatically improving the plant's overall energy balance. • Reduced Operating Costs: Lower moisture transport means less energy spent moving water through the system and lower tar production in the gasifier, simplifying cleanup.

Inquire About SERVODAY Boiler & Gasifier Feeding Solution for Bio-Methanol Plant

Are you ready to elevate your Wood & Biomass Feedstock Handling & Storage Systems for Bio-Methanol Production to new heights? Contact us today to request a quote. Discover the perfect solution tailored to your feedstock needs, offering a customized quote that aligns with your budget and requirements.

Versatile Biomass Handling for Uninterrupted Production

Engineered for Diverse Methanol Feedstocks

SERVODAY's specialized biomass feed systems are engineered to handle the wide variety of materials used in bio-methanol production, including wood chips, forestry residues, agricultural byproducts, and biomass briquettes. This feedstock flexibility ensures your plant can maintain continuous operation, adapting to material availability without compromising efficiency in the gasification process.

Built for 24/7 Methanol Production

Maximum Uptime for Continuous Gasification

Engineered for relentless operation, SERVODAY’s robust biomass feeding systems deliver exceptional reliability for around-the-clock methanol synthesis. The heavy-duty construction withstands the abrasive nature of biomass fuels, providing consistent, trouble-free feeding to your gasifier or boiler to ensure stable syngas production and maximize plant availability.

Precision Feeding for Optimal Gasification

Custom-Engineered for Syngas Boilers

SERVODAY provides customized boiler feeding solutions specifically engineered for bio-methanol plants. Our systems are tailored to handle the specific fuel characteristics of feedstocks like wood chips, eucalyptus, and industrial biomass residues, ensuring precise and reliable fuel delivery to CFB, BFB, and gasifier boilers for superior syngas quality and consistent methanol output.

Expert Support for Peak Plant Performance

Comprehensive Operational Training

SERVODAY ensures your team achieves mastery with extensive training programs focused on bio-methanol production. From feedstock handling best practices and system maintenance to troubleshooting specific to gasification processes, our training maximizes operational efficiency, safety, and the longevity of your complete biomass-to-methanol system.